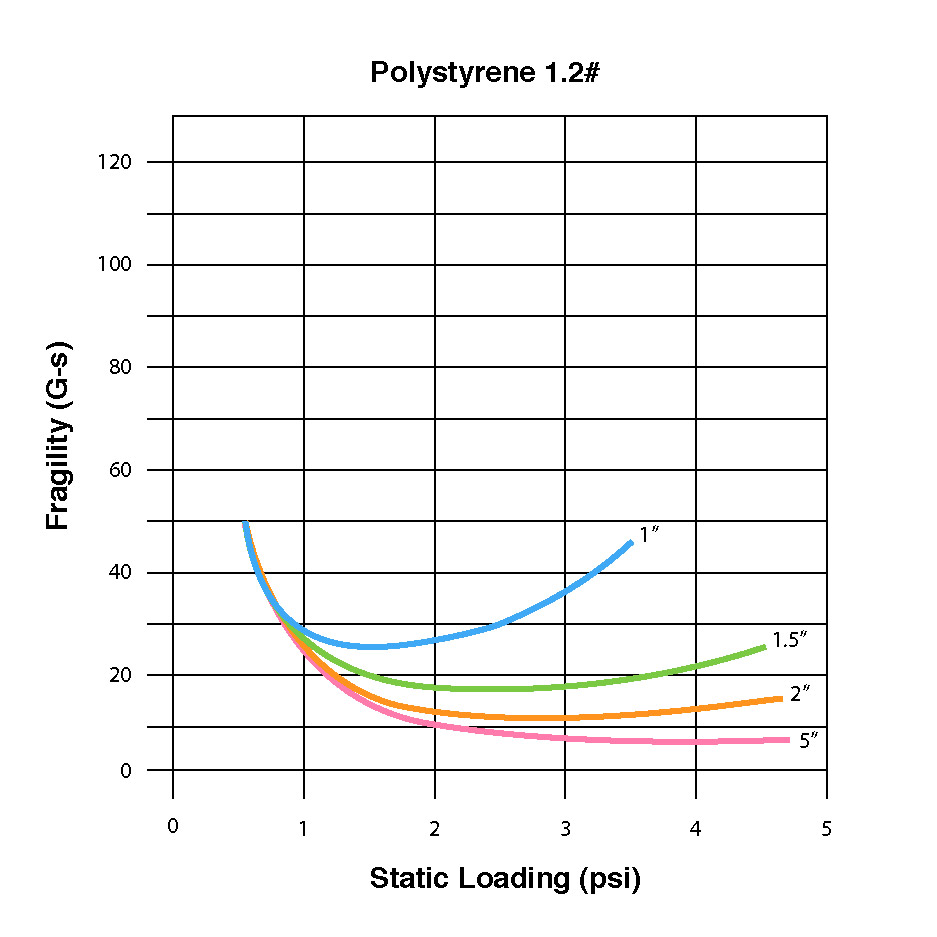

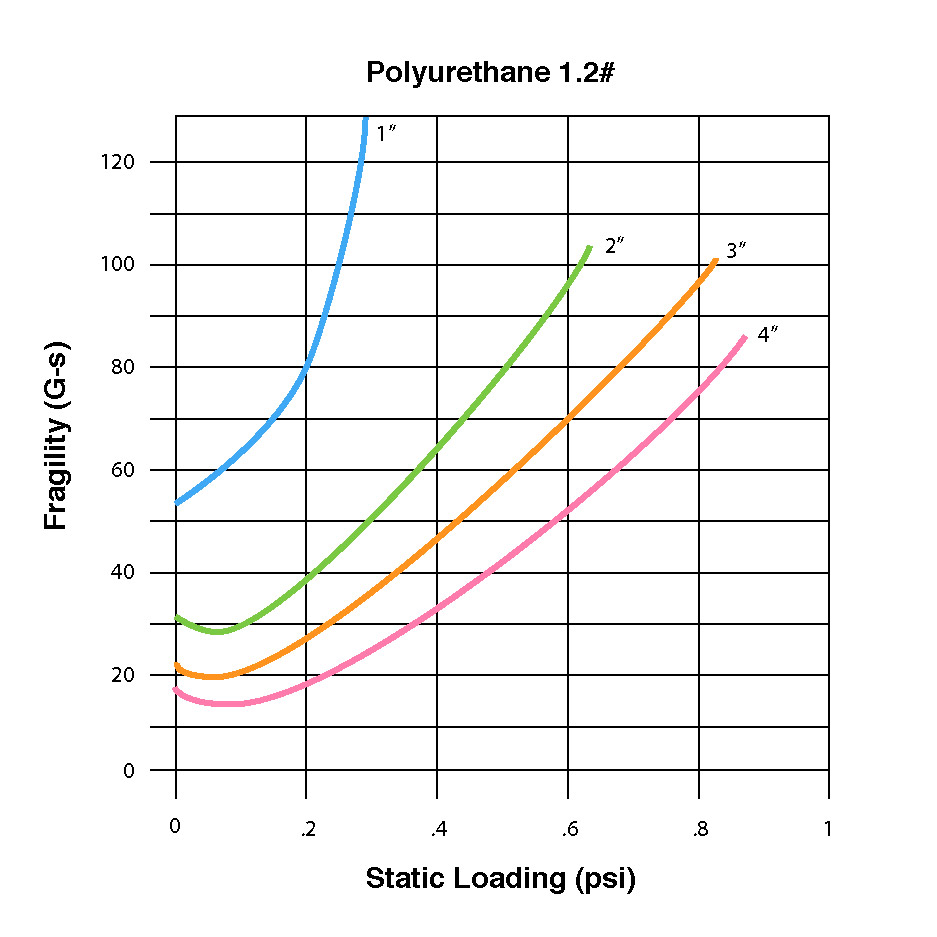

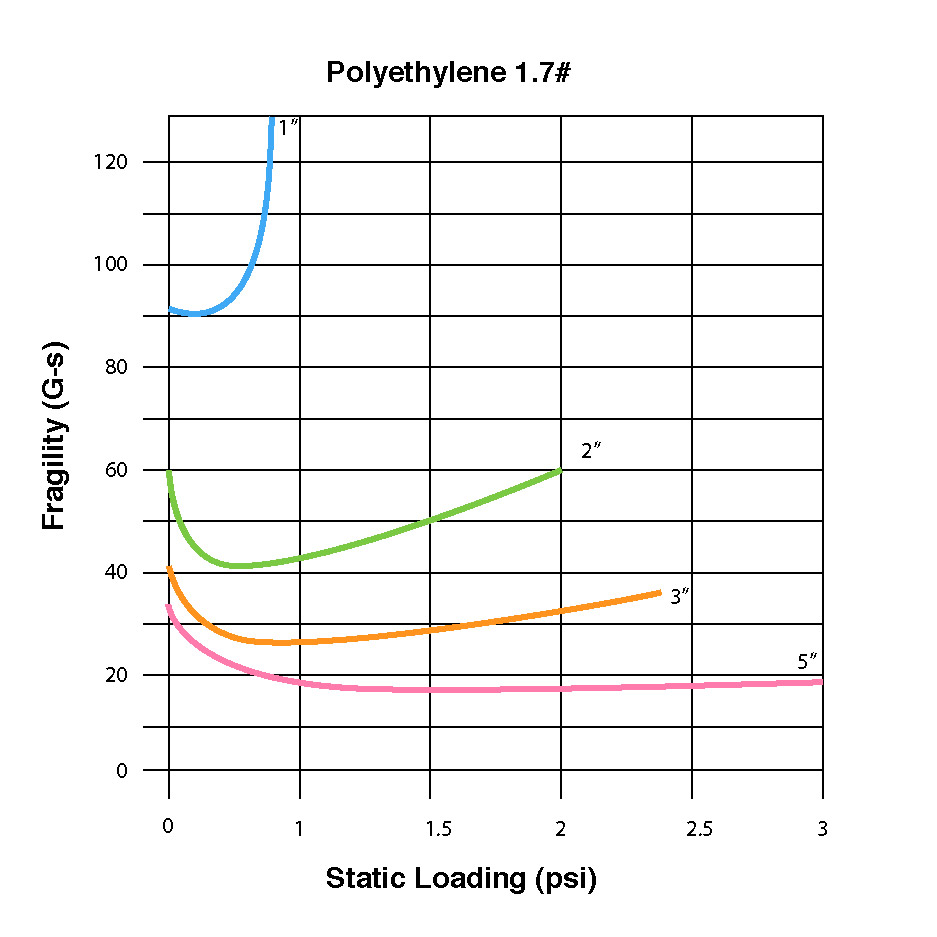

Drop TestingOur recommended approach: Normally we can design a package quickly and efficiently based on basic information about the item, such as weight, shipping method, the customer’s past damage experience. We combine this information with our engineering judgment and knowledge of drop test curves to design a packaging prototype for testing. We then assess our proposed design in our drop test lab, attempting to exceed the minimum required drop test height for your shipping method. Only after successful testing do we propose our design to the customer. This method is light on engineering resources, allowing us to rapidly and cost-effectively develop a reliable design. When Precision Trumps Cost: This method is very resource intensive and suitable only for large volume manufacturers of especially fragile products; however, when customers require a fail proof design to perform at large volumes, a rigorous testing process can be undertaken. Initially, the fragility of a product is determined by subjecting it to a series of gradually more severe shocks (deceleration) in order to find the lowest severity impact that will damage the product. The highest deceleration, which did not cause damage, is then known to be the product’s G-factor. Only after this G-factor is determined do we design and test the package itself. Sample Drop Curves, by material:       |  DropTest_graphs-01-1 |  DropTest_graphs-02-1 |  DropTest_graphs-03-1 |  DropTest_graphs-02-2 |  graph_foam_1 |  graph_foam_2 |  graph_foam_3 |